With over 4.66 billion active internet users worldwide and a 30.8% increase in business activities conducted online last year, it’s no secret that a secure internet connection is a necessity for a vast majority across the globe.

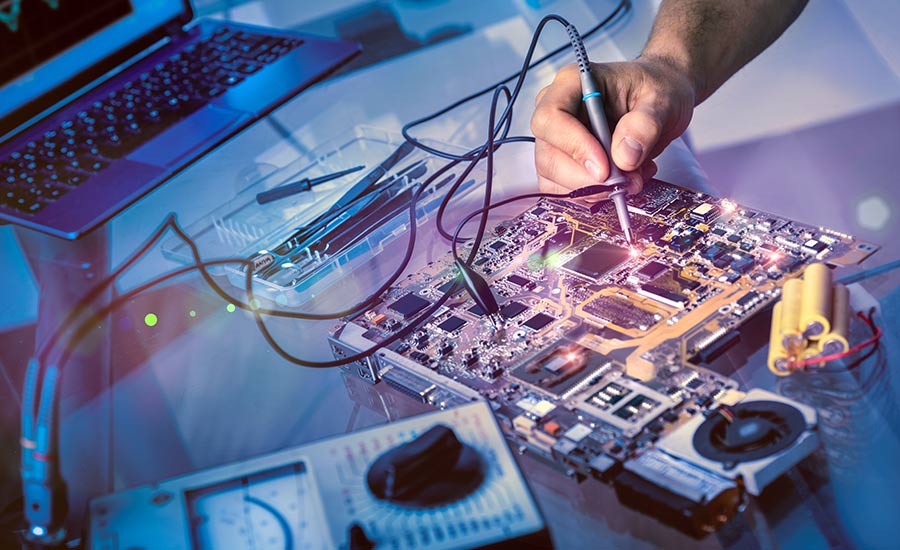

It’s easy to forget that much like other pieces of equipment, high-quality, uninterrupted internet signals require routine equipment maintenance to function properly.

When equipment processing the internet connection fails, millions of people are affected instantly, whether they’re engaging in online shopping, streaming movies or connecting with co-workers over video chat.

Not only can delayed maintenance cause service interruption, it can also lead to a whole host of problems for businesses, including skyrocketing costs down the road.

In this blog, we’ll cover everything you need to know about the hidden cost of delayed equipment maintenance. Plus, we’ll detail our equipment maintenance and repair services, for GPON, headend equipment and more at Commercial Electronics, Inc.

What Is Delayed or Deferred Maintenance?

Delayed maintenance, also known as deferred maintenance or backlog maintenance, refers to maintenance activities that end up being postponed or rescheduled – often to be forgotten about entirely.

While deferred maintenance is often unintentional or due to circumstances that may seem out of a business owner’s control, it can be damaging and even dangerous in some situations.

Common Causes of Deferred Maintenance

Causes of deferred maintenance range from lack of funds to lack of organization across the company. Here are a few of the most common causes of deferred maintenance:

- Lack of funding

- Lack of specialists to perform maintenance activities

- Missing spare parts due to inventory errors or storeroom mismanagement

- Lack of time allocated to maintenance activities

- Lack of priority and organization

- Negligence

- Inadequate preventive maintenance measures

- Company policies that include run-to-failure maintenance

Regardless of the cause, the end result is typically the same – and that’s where the hidden cost of delayed maintenance comes in.

The Hidden Cost of Delayed Equipment Maintenance

While deferred maintenance may go unnoticed for a short period of time (or even a long period of time in some cases), it’s usually noticed when it’s too late.

Delayed maintenance is similar to accruing debt: if you skip payments, the amount you owe continues to rise and bring interest along with it. If you fail to maintain your equipment as needed, additional expenses are undoubtedly around the corner.

Let’s look at a few major issues that can arise due to delayed equipment maintenance – all of which can carry a hefty bill along with them.

Faulty Or Inefficient Operation

When poorly maintained, equipment is typically unable to run at full capacity. Failure in one area may be compensated by other areas to keep the equipment operational, which can result in slower output and increased operating costs.

For example, damaged coaxial cables or faulty splitters can result in poor TV picture.

System Failure

If a complete system fails, the results can be disastrous. Imagine a complete failure of internet services in a call center, trading company or financial institution – all of which rely heavily on internet for daily operation.

Safety Risks

If your equipment is not properly maintained, it can lead to serious safety risks for employees and others.

For example, if equipment that transmits cable and internet to a home is not properly maintained, it could fall from a telephone pole and injure passersby.

Equipment Damages

Lack of proper maintenance can increase the risk of wear and tear of your equipment, and one problem could easily snowball and create additional problems, driving up costs for repair or replacement.

Loss Of Data

Poor maintenance on equipment that holds data, such as regular memory backup and security updates, can lead to massive data loss and other costly issues, including reputation damage.

If your company holds data for customers or businesses, and this data is lost or leaked due to improper maintenance on your equipment, it can do serious harm to your company.

Reduced Equipment Life

Proper maintenance helps prolong equipment life. When your equipment is not functioning optimally, components wear faster, affect other elements and reduce the equipment’s life.

Emergency Repair Costs

Emergency repair can cost several times more than planned repair or maintenance.

Additional faucets of emergency repair, such as waiting for spare parts to arrive, can lead to disruption of operations, which can accrue additional costs.

Downtime

Yet another effect of delayed maintenance is downtime that occurs when equipment fails. Failure of equipment that is critical to an industry can mean huge financial losses, unhappy customers, a damaged business reputation and more.

How To Avoid The Hidden Costs Of Delayed Equipment Maintenance

No business owner wants to be surprised with additional costs for emergency equipment repair and other issues due to deferred maintenance. Of course, the obvious answer is to plan regularly scheduled maintenance for your equipment and adhere strictly to the schedule.

In addition:

- Audit your current maintenance processes and projects: Identify the causes for your maintenance backlog and find solutions to improve the processes and eliminate the obstacles for regular maintenance.

- Log your maintenance activities in a software platform: Use a cloud-based software platform to keep your information centralized and secure. Store service requests, equipment documentation, maintenance locations and work order history in one organized place.

- Prioritize your deferred maintenance tasks: Use categories to group tasks under “immediate attention” and “delayed attention” labels. Place the tasks that are essential to your normal operation or may be cited for safety violations in the “immediate attention” group. Set a certain time frame for the “delayed attention” group and prioritize the tasks in that group once you have dealt with the urgent tasks.

- Follow a strict preventive maintenance program: Create a list of your asset categories and define the preventive maintenance tasks for each asset. Plan maintenance activities to service the asset in advance.

- Analyze the life cycle cost of your critical equipment: Detail the costs for your equipment and understand how poor maintenance eventually costs more than preventive maintenance measures. Forecast adequate funding for maintenance reserves.

- Research the preventive maintenance best practices in your industry: Consult resources about your industry to become knowledgeable about tips and tricks to help you stick to a preventative maintenance schedule.

- Work with financial professionals: Work with your internal finance team or an external financial advisor to help you budget for preventative maintenance to ensure a longer life for your equipment.

Equipment Repair at Commercial Electronics Inc.

If you have delayed maintenance for too long and your equipment needs repair, Commercial Electronics Inc. can help.

With over 50 years of experience, our experts repair, refurbish, upgrade and replace various types of equipment, including:

- Headend equipment

- Line equipment

- CATV Fiber Optic equipment

- Gigabyte Passive Optical Network (GPON) equipment

- Power supply equipment

We pick up, repair, and drop off your equipment while sharing an electronic record of the entire process with you, so you can focus on your business while we do the rest.

Our experts:

- Inspect your equipment for physical damage

- Remove corrosion and clean your equipment

- Modify and upgrade your equipment

- Conduct repairs and test your equipment to make sure it meets the manufacturer’s specifications

- Execute QC tests and record repair data in our reporting software solution, CEREUS

What’s CERUS? We’re glad you asked.

CEREUS is a web-based solution that gives you access to your equipment repair data and allows you to track your equipment at all times. We offer it free to our repair customers and all data is available for secure export and download.

At Commerical Electronics, Inc., we also help you track the life cycle of your equipment with NESS.

NESS is the first virtual inventory tracking and repair tagging system.

With NESS, you can:

- Follow your equipment through its entire life cycle

- Know where your equipment is at all times

- Use virtual instead of physical repair tags

- Monitor your repair status

Need to schedule a pick up?

Contact us!Avoiding The Hidden Cost of Delayed Equipment Maintenance: Key Takeaways

Delayed maintenance of your equipment can have a laundry list of negative effects on your business such as:

- Safety risks

- Equipment damages

- Reduced equipment life

- Data loss

- Downtime

- Emergency repair costs

- Inefficient operation

To avoid delayed maintenance costs:

- Conduct regular audits of processes and projects

- Use a software platform to log your maintenance activities

- Prioritize your maintenance tasks

- Implement a thorough maintenance program

- Research your industry preventive maintenance best practices

At Commercial Electronics Inc., we provide high quality repair services at lower costs for GPON, headend, power supply, fiber optic and line equipment, paired with inventory tracking and analysis tools to optimize your repair and inventory processes.

To save your time, we offer equipment pick up and drop off services while sharing every step of the repair process with you.